Industrial Water Treatment Systems

Custom Solutions to Cut Processing, Labor and Filtration Costs

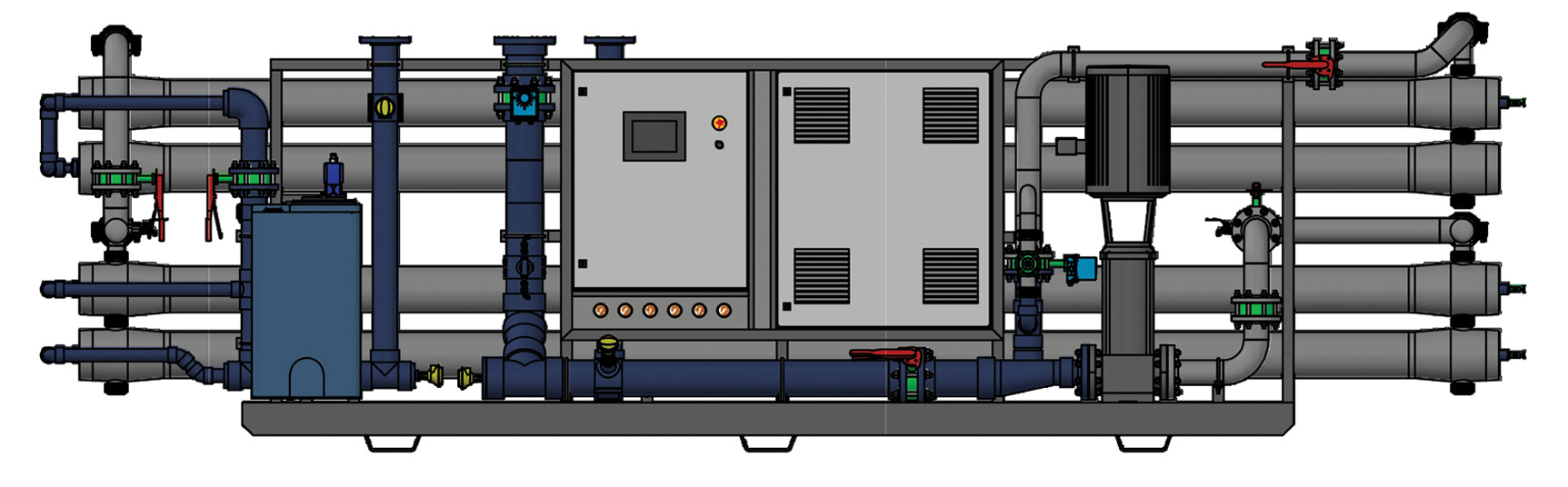

Industrial Reverse Osmosis

Pargreen Water Technologies (PWT) offers design/build capabilities for Industrial Reverse Osmosis systems. We are a provider of pre-engineered Reverse Osmosis (RO) systems from GE Osmonics and other RO specialty manufacturers.

The Industrial RO group specializes in 2.5”, 4”, and 8” membrane element systems – with capabilities from 1-1000+ gallons per minute (gpm).

Along with the Industrial Reverse Osmosis, Pargreen Water offers additional membrane technologies including microfiltration (MF), nanofiltration (NF), and ultrafiltration (UF) equipment (cross flow & dead-end options.)

Pargreen Water RO element arrays can be configured in PVC, fiberglass, or stainless steel housings. Systems come skid mounted with materials to spec and multiple controls options included custom PLC & SCADA choices.

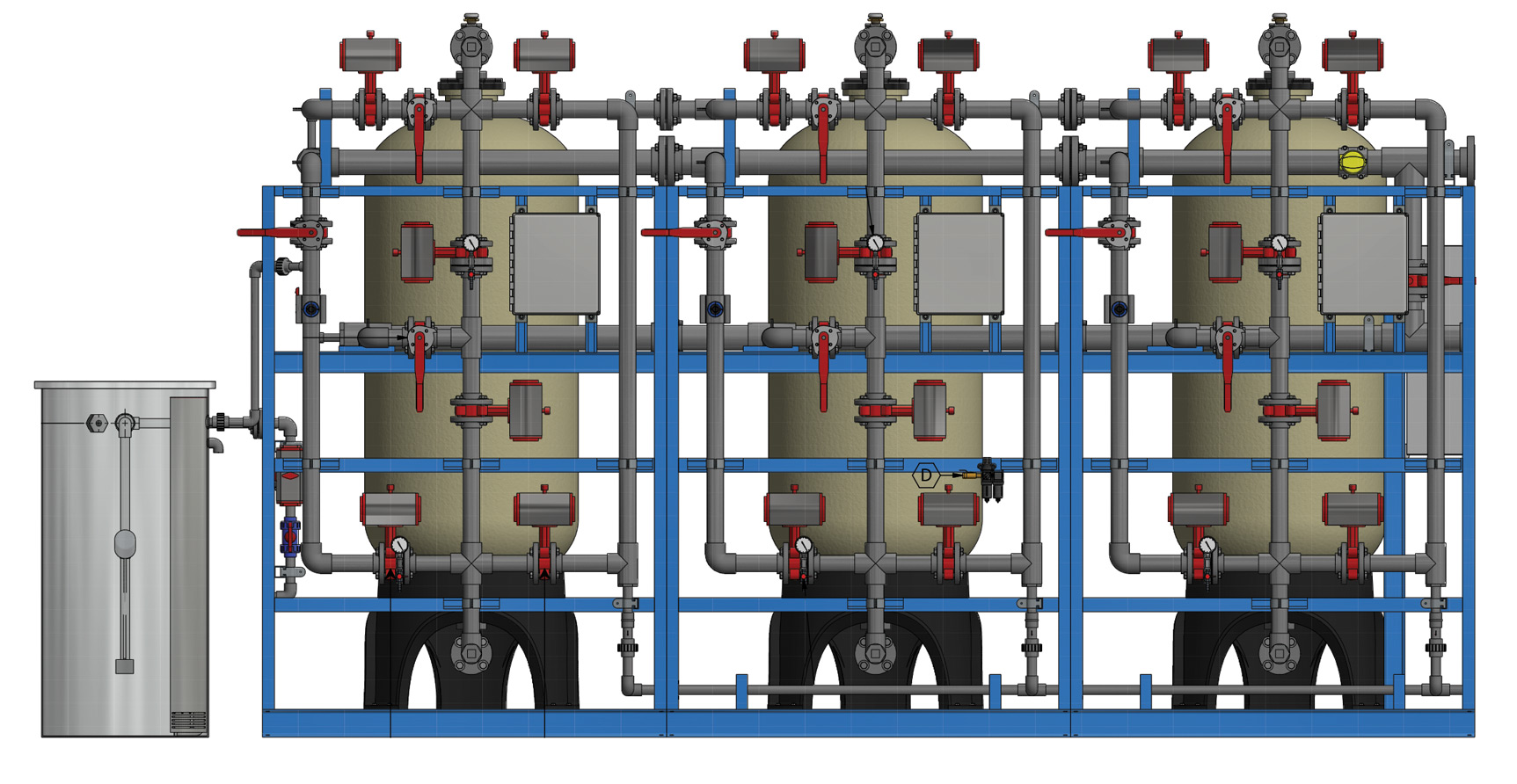

Industrial Water Softeners

Pargreen’s technical advisors have decades of Industrial Water Softener experience. Our design staff can help you match the best technology with your flow rate, volumetric, and soft water requirements.

Industrial Softeners come in many configurations. We offer both standard downflow systems as well as ultra-high efficiency upflow softeners, brine recovery, and water reclamation system. These features can be incorporated for substantial water and salt savings.

Both fiberglass and steel vessels with ASME stamp are available. Controls and piping range from multi-port valves or valve nests, to multiple tank options. Material offerings include Noryl, steel, stainless steel, PVC, or copper.

Control options range from manual, timed, metered, to progressive regeneration options. Water quality and/or usage can be monitored to assured quality standards.

Our technical staff can perform an intake audit of a client’s system. We may find options for upgrades and/or increased efficiency. You will be confident the system is designed correctly for the job and produces the water quality you need.

Bag Filters

For over 40 years, Pargreen has provided high quality, innovative filtration and separation solutions to satisfied customers throughout the Midwest.

We have successfully helped our clients reduce their overall costs by cutting processing times, eliminating filtration steps, trimming labor expense and reducing filter costs.

Pargreen staffs an entire team of inside and outside support for filtration/separation technologies and dead-end filtration applications. Please visit: www.pargreen.com for more information.

Media Filters

Media Filters are commonly used to remove iron, manganese, suspended solids, and other waterborne particulates.

Filter media options are selected based on application. Systems can be engineered with Carbon, Greensand Plus, multi-media, zeolite, pyrolusite, and designer medias.

Energy efficiency and uninterrupted flow are important to consider in running a media filtration system. Pargreen Water offers automatic pressure drop backwash systems to meet these needs, in addition to standard timer-controlled backwash systems.

With multi-port valves and valve nest options, and permanent or skid mount configurations, PWT Media Filtration Systems can fit any requirement and location.

PWT can provide service, pilot studies, and operational audits on media-based systems. The service team works with both pneumatic and hydraulic operators and actuated butterfly, diaphragm and ball valves – from 1-8”.

The technical advisory team has over 60 years’ experience designing media filtration systems. We stand ready to assist clients in developing a working plan or conduct a pilot to test best practices.

For more information on our Industrial Water Treatment Systems, contact Pargreen or call 800-323-2810.